Single Ply Roofing

These roof systems use TPO, PVC, and EPDM. They are incredibly flexible, robust, materials preferred by many building owners because it resists peeling, cracking and other types of weathering. Their main characteristic is they are designed to be installed in a single layer. There are two main categories within the single-ply roofing industry – thermoplastic membranes and thermoset membranes.

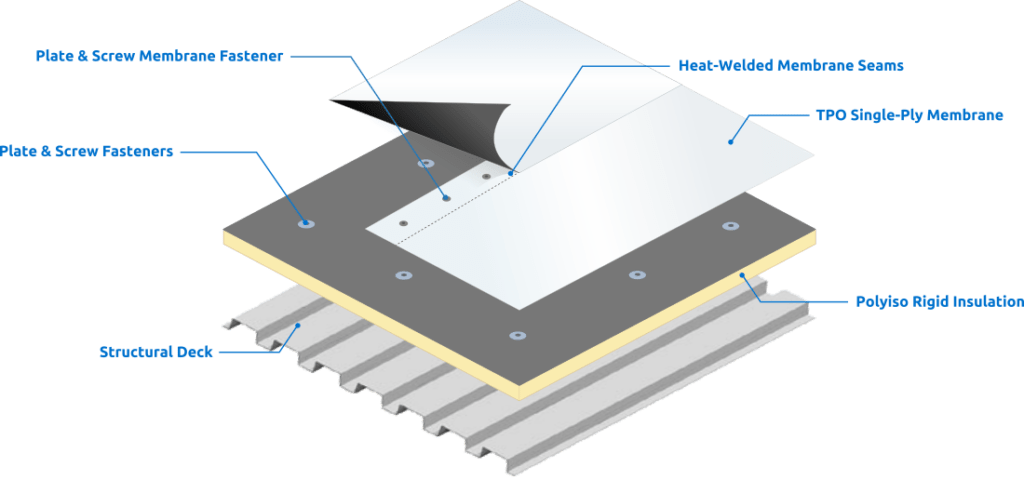

TPO (Thermoplastic Polyolefin)

This material is most commonly used on low slope roofs in North America and includes reinforced roof sheets that feature heat-welded seams and are highly reflective. TPO is a single-ply membrane, typically composed of polypropylene and ethylene-propylene rubber that has been polymerized together. TPO is part of the thermoplastic membrane category and comes in a variety of colors, although the most popular are white, grey and tan. The membrane can be installed using several different methods including mechanically attached, adhered, or ballasted.

PVC (Polyvinyl Chloride)

PVC roofing material is composed of two layers of PVC with a polyester reinforcement scrim in between. The top ply contains additives that make the membrane UV resistant. The bottom ply is typically darker and contains plasticizers for flexibility which helps make installation easier. Other benefits of a PVC membrane are longevity, durability and fire resistance. PVC is also weldable which means it can be welded to an adjoining sheet making it watertight. PVC sheets can be made to resemble a standing seam roof system by welding a pre-manufactured rib to the surface which creates a visually appealing aesthetic for a much lower price point. PVC membranes are also recyclable and can be reused in new sheets.

EPDM Roofing (Ethylene Propylene Diene Monomer)

What is EPDM roofing? The letters stand for “ethylene propylene diene monomer,” a tough-to-pronounce chemical compound that is known for its elasticity and toughness. EPDM roofing employs a material that has a fantastic ability to resist the constant bombardment of ultraviolet light and all the sun’s damaging rays. One of the most popular commercial roofing materials in current use, EPDM rubber roofing is doubly desirable because it combines low cost with resilient strength. An EPDM roofing membrane is a type of synthetic rubber composed of natural gas and oil. EPDM roofing material is used in low-slope commercial buildings all over the world.

PVC (Polyvinyl Chloride)

PVC roofing material is composed of two layers of PVC with a polyester reinforcement scrim in between. The top ply contains additives that make the membrane UV resistant. The bottom ply is typically darker and contains plasticizers for flexibility which helps make installation easier. Other benefits of a PVC membrane are longevity, durability and fire resistance. PVC is also weldable which means it can be welded to an adjoining sheet making it watertight. PVC sheets can be made to resemble a standing seam roof system by welding a pre-manufactured rib to the surface which creates a visually appealing aesthetic for a much lower price point. PVC membranes are also recyclable and can be reused in new sheets.

EPDM Roofing (Ethylene Propylene Diene Monomer)

What is EPDM roofing? The letters stand for “ethylene propylene diene monomer,” a tough-to-pronounce chemical compound that is known for its elasticity and toughness. EPDM roofing employs a material that has a fantastic ability to resist the constant bombardment of ultraviolet light and all the sun’s damaging rays. One of the most popular commercial roofing materials in current use, EPDM rubber roofing is doubly desirable because it combines low cost with resilient strength. An EPDM roofing membrane is a type of synthetic rubber composed of natural gas and oil. EPDM roofing material is used in low-slope commercial buildings all over the world.

Modified Bitumen Roofing Systems:

A modified bitumen roof combines asphalt and a unique chemical polymer for flexibility and temperature resistance. It can be applied in multiple layers, several ways (self-adhesive sheets, hot-mopped asphalt, torch applied or cold-applied adhesives), in both hot and cold temperatures, making it a viable option for installation through all four seasons. The seams are melted together to form a secure bond. They are rated against wind, fire, and hail which means they are resistant to damage during a storm.

Built-Up Roofing Systems

Among the oldest roofing systems available on the market, built-up roofing consists of 3-5 layers for enhanced protection, especially in extreme climatic conditions with wide ranges of low and high temperatures. Sometimes called BUR for short, built-up roofing has been around for more than 100 years.

Metal Roofs

Metal roofing is known for its aesthetics, longevity, and durability. Used on both low-slope and steep roofs, many building owners prefer the look and durability that comes with metal roofs. Building and homeowners are now opting for certain types of metal roofs to take advantage of the longer lifespan and durability compared to a traditional shingle roof.

Liquid Applied Roofing

A liquid applied roofing membrane is constructed in place with resin and a reinforcing polyester. It offers superior waterproofing capabilities because it’s able to reach those harder to get to areas. It is sprayed on, or roller applied, usually in two separate coats. A liquid roof, due to the nature of how it is applied doesn’t create invasive disturbances and or emit harmful or strong odors, making it a good option for when businesses need to stay open during construction.

Roof Coating Systems: This fully adhered coating consists of a fluid-applied membrane. It can stretch and return to its original shape. There are many types of roof coatings, but the most common include acrylic and silicone. Best suited for metal roofs, coatings can help keep buildings cool, reduce energy consumption, protect against leaks and extend the life of a commercial roof.

Photovoltaic (PV) Solar Panels

Solar panels absorb natural sunlight and convert it into usable energy. In roofing, photovoltaics have the potential to generate long-term cost savings to the users, especially in high-sun geographic regions. When installing a rooftop photovoltaic system, Nations Roof® can help you maintain the integrity of the roofing system to keep your building watertight without interrupting the service of the PV system.

Steep Slope

Steep slope roofing refers to roofing materials suitable for roofs that have slopes of 3:12 or higher. While this is mainly seen in residential properties, commercial buildings sometimes have this style of roof, usually because it’s a design feature of the building, e.g., a hotel or university. The roof slope affects the materials that can be used which range from asphalt composition roll, fiberglass 3-tab shingle, fiberglass laminate (architectural) shingle, specialty asphalt shingle, through to wood shakes, wood shingle, clay, concrete tile, slate, and metal.

Insulation & Cover Boards

Cover boards and thermal insulation’s enable a roof to improve the energy efficiency of your building and lower your utility bills. The perfect time to add insulation and meet current energy codes is when the roof is being replaced.

ACRYLIC COATINGS

Acrylic water-based coatings are ideal for high UV environments where a reflective roof is desired. They can be colored, but generally are sold in white, tan, and grey. Many specialized versions are made to be compatible with specific substrates.

ASPHALT COATINGS

Asphalt coatings are either solvent based “cutbacks” or emulsions. They can be black or aluminized. They can be used in cold and inclement weather. Aluminized coatings are used when a reflective and UV stable asphalt coating is needed.

POLYURETHANE COATINGS

Polyurethane coatings are typically solvent based and come in two main types, aromatic (less UV stable) and aliphatic (very UV stable). Urethanes have good mechanical properties and high abrasion resistance. They are suggested for use in hail prone regions or where a roof is exposed to heavy foot traffic.

SILICONE COATINGS

Silicone coatings, like acrylic coatings, perform well in high UV environments where a reflective roof is desired. Often silicone is used in locations where rain is a daily occurrence, or if the roof is often wet and experiences excessive amounts of ponded water.