Quality Local TPO Roofing

Many people are looking to replace or install a flat roofing system. They want to protect their buildings from the elements, keep them dry, and ensure that their investment lasts as long as it can.

TPO Roofing Contractors

TPO Roofing is often chosen by companies for its low cost. The material and installation costs are generally comparable to EPDM. PVC can also be considerably cheaper if you have a large area to cover.

TPO’s white coloring reduces energy consumption which will help to lower your building’s ongoing energy costs. TPO can often be attached to the roof decking with heat welding. TPO resists corrosion so it’s extremely mildew-, mold-, and algae-resistant. TPO also doesn’t need regular power washing.

What's a TPO Roofing System?

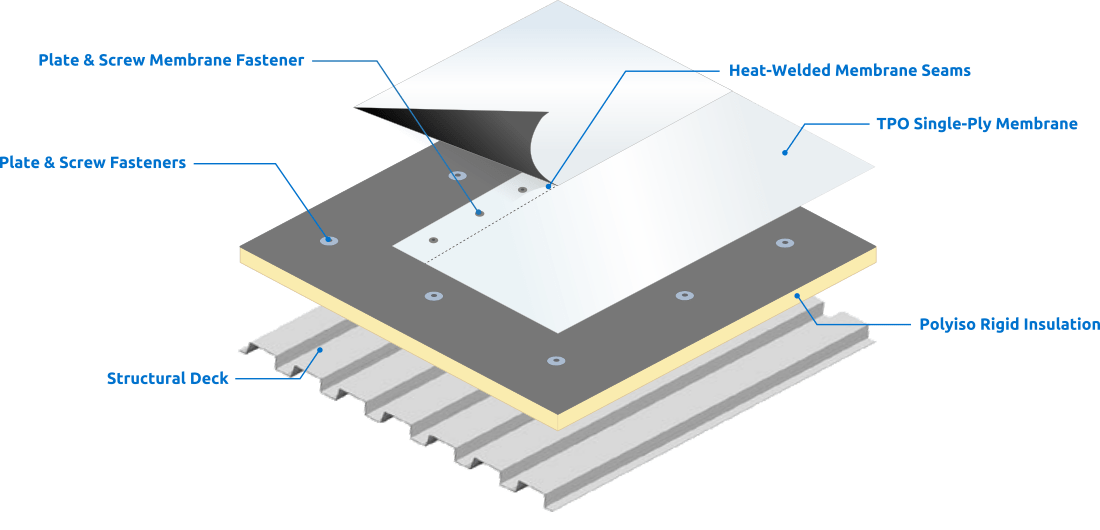

TPO is for “Thermoplastic Polyolefin,” which is a single-ply roofing membrane. It’s a rubber roofing material made from one layer of rubber, and not multiple layers. This reduces complexity and minimizes leak-causing errors. It is also 100% recyclable.

Customers often recognize TPO as the “white roof” that covers a building. This helps to reduce its energy consumption. TPO sheets come in a variety of colors, including tan and white. They reflect more UV radiation (heat), which keeps your building cool in summer. This can reduce your electricity bill.

Here are some quick benefits to TPO:

Strong, versatile and adaptable.

TPO sheets are made to resist tearing, punctures, and impacts. This means that even if a tree branches falls on the roof or hail storms through, it won’t cause any significant or costly damage to the roof.

Cool Roofing

TPO is made in a light shade, reflecting the sun’s energy away. This reduces building energy costs and also lowers AC costs during the summer.

It’s ECO Friendly

TPO is free of toxic substances and hazardous ingredients. It can be 100% recycled, which reduces building energy consumption.

Easy and Economical.

TPO membranes tend to be less expensive to maintain over time than other flat roofing types. They are also mechanically attached and heat adhered to insulation boards (not glue). This means that roof installation is quick and easy, which saves labor costs.

Seams can be heat-welded

TPO roofing sheets are heat-welded together at the seams to form a strong bond. Because there are no blow-torches (like in modified bitumen), there is no risk for a fire or higher insurance costs.

Also, seams are often the weakest component of commercial roofing systems. However, with TPO, the fused seams create a stronger area than all the coverage.

How long does TPO last?

TPO roofing compounds have evolved in recent years and can vary from manufacturer to manufacturer. TPO roofs are typically rated for a lifespan of 15-20 years. However, they can be rated for a maximum of 10-15 years. Many roofing materials have warranties that last for between 30-35 years. TPO roofs can reach their age limit due to gradual membrane degradation. TPO is a newer roof formula so many haven’t had the chance to use it for 30 years.

As with any other type of roofing system the quality of the installation is the most important factor that will determine how long your investment will last. It is the quality of the installation that will determine how long your roof will last, how likely there are to be leaks and how frequently maintenance will be required. If you want to maximize the lifetime value of your roof, you need to choose a qualified roofing contractor.

The quality of the manufactured materials is the final factor that will affect your roof’s longevity. Conklin, one of the top-rated TPO manufacturers, offers a 25-year warranty.

TPO is the best option if you are looking for a roof that will last for at least 10-15 years. PVC is a good choice if you want a roof that will last 20 years. It has been thoroughly tested against the elements and time spent in manufacturing.

FAQ

Most frequent questions and answers

TPO roofing can be installed fully-adhered, mechanically-attached or ballasted. TPO roofing attaches to its substrate using a TPO roofing adhesive. This adhesive creates a strong chemical bond with the TPO. Attaching mechanically attached TPO roofs onto the roof substrate is possible using special screw-type fasteners. Finally, you can apply a TPO membrane to the roof surface once it has been ballasted. The perimeter and penetrations are used to support the roof membrane.

TPO (thermoplastic-polyolefin), which is a single-ply roofing system, covers the roof’s entire surface. TPO, rather than being a type of plastic, is actually a mixture between different types of rubber. Most commonly, it is a blend from polypropylene, ethylene-propylene rubber.

The main difference is that EPDM has a darker surface which absorbs heat from the sun. In summer, this will make your air conditioner units work harder. TPO roofing is lighter and will reflect sunlight. Commercial air conditioners are able to work more efficiently due to its white color. White EPDM is also available, but it’s more costly. TPO is less puncture-resistant than EPDM. EPDM can be installed and repaired more easily, however EPDM is generally cheaper. TPO, which is a more recent technology, is still being refined. EPDM, on the other hand is more established and proven.